CERRO® ALLOYS

CERRO® products are low melting temperature alloys used as thermal fusibles for forming or temporarily fixing parts. They are used in applications such as eyewear, the manufacture of spatial parts and aeronautics.

The METACONCEPT Group offers a range of specific alloys whose melting temperatures, guaranteed by the precise composition of the alloy, provides the behavioural change required (solidus/liquidus) in safety systems or when forming parts in industrial or medical fields.

These products are supplied as bars or small ingots; they can also be manufactured in the form of sticks, flat bars or large ingots. Fusible alloys undergo dimensional changes (expansion/shrinkage) depending on the casting and cooling time. Generally, fast casting with a cooling time of less than 15 minutes optimises stability.

The METACONCEPT Group collects used baths,off-cuts, scraps and white metal oxides. Contact our recycling department to find out more.

|

Item no.

|

Designation

|

Form

|

Solidus/Liquidus

|

Density g/cm3

|

Brinell hardness

|

Expansion in %*

|

Packaging

|

|---|---|---|---|---|---|---|---|

|

FB103300

|

CERRO® 103°

alloy |

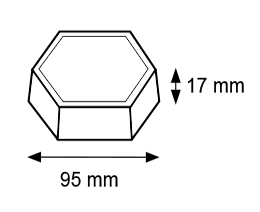

Small marked ingot

Around 1 kg |

Eutectique 103°

|

8.67

|

14,2

|

+0,03

-0,02* |

Bulk/Box

|

|

FB183300

|

CERRO® 103°

alloy |

Small marked ingot

Around 1 kg |

Eutectique 183°

|

8,78

|

NC

|

NC

|

Bulk/Box

|

|

FB124300

|

CERROBASE®

alloy |

Small marked ingot

Around 1 kg |

Eutectique 124°

|

10,3

|

10,2

|

-0,08

+0,22* |

Bulk/Box

|

|

FB073300

|

CERROBEND®

alloy |

Small marked ingot

Around 1 kg |

70° – 73°

|

9,4

|

9,2

|

+0,25

+0,57* |

Bulk/Box

|

|

FB170300

|

CERROCAST®

alloy |

Small marked ingot

Around 1 kg |

138°- 170°

|

8,2

|

22

|

-0,01

-0,01* |

Bulk/Box

|

|

FB047300

|

CERROLOW® 47°

alloy |

Small marked ingot

Around 1 kg |

Eutectique 47°

|

8,9

|

12

|

+0,05

-0,02* |

Bulk/Box

|

|

FB070300

|

CERROLOW® 70°

alloy |

Small marked ingot

Around 1 kg |

Eutectique 70°

|

9,73

|

14

|

+0,25

+0,57* |

Bulk/Box

|

|

FB227300

|

CERROMATRIX®

alloy |

Small marked ingot

Around 1 kg |

103°- 227°

|

9,5

|

19

|

+0,08

+0,61* |

Bulk/Box

|

|

FB090300

|

CERROSAFE®

alloy |

Small marked ingot

Around 1 kg |

70° – 90°

|

9,4

|

9

|

-0,04

+0,25* |

Bulk/Box

|

|

FB096300

|

CERROSHIELD®

alloy |

Small marked ingot

Around 1 kg |

Eutectique 96°

|

9,87

|

14

|

-0,4

+0,25* |

Bulk/Box

|

|

FB138300

|

CERROTRU®

alloy |

Small marked ingot

Around 1 kg |

Eutectique 138°

|

8,2

|

22

|

+0,07

+0,05* |

Bulk/Box

|

*après 2mn 200h

|

Designation

|

Uses

|

Characteristics

|

|---|---|---|

| CERROLOW® | Very low melting temperature. Imprints, work with optical lenses | CERRO® trademark® |

| CERROBEND® | Tube bending, various types of settings, protective radiotherapy screen | CERRO® trademark® |

| CERROSAFE® | Sprinklers, imprints, models | CERRO® trademark® |

| CERROMATRIX® | Dies, anchorings and other fasteners | CERRO® trademark® |

| CERROBASE® | Dies | CERRO® trademark® |

| CERROTRU® | Moulds, models, dies, settings, electroforming mandrels * Guaranteed to be lead-free and cadmium-free |

CERRO® trademark® |

| CERROCAST® | Moulds, models, dies, settings, electroforming mandrels * Guaranteed to be lead-free and cadmium-free |

CERRO® trademark® |

| CERROSHIELD® | Protective radiotherapy screen | CERRO® trademark |

(*) Lead-free alloys – European standard no. 2000 / 53 / CE

The product safety information sheet below is available upon request from the METACONCEPT Group.

The implementation method is specific to each workshop and depends on the alloy and its application.

In all cases, the metal needs to be placed in a crucible.

Bring the temperature of the alloy to 20°C above the temperature of its liquidus. You can then pour the molten metal into the mould prepared for this purpose.

Let it cool, taking into account possible expansion or shrinkage.

After use, the alloy may be re-melted and reused.

If this application is repeated frequently, it would be wise to contact the METACONCEPT Group so that they can conduct a metallurgical analysis and potential purification. Indeed, contaminants such as metal from the mould and oxidation from the surrounding air could slightly alter the composition of the alloy.

To prevent burns caused by the molten metal, it is advisable to wear a protective apron, shoes, gloves, helmet and glasses.

Do not smoke at the workstation.

The workstation must be well ventilated.

Wash your hands when leaving the workstation.

Comments:

Contact our technical department to ascertain which product is most suited to your application.

All of the information contained in this document is provided for informational purposes only and the METACONCEPT

Group will not be held liable for it.