Ingots

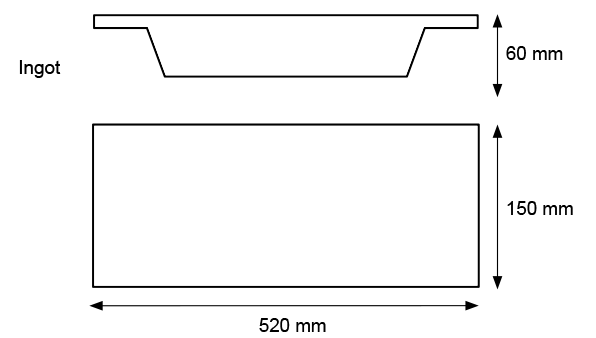

The METACONCEPT Group supplies pure metal ingots as well as alloys in the form of various sized ingots and billets. The billets are vacuum cast in just one step and therefore offer the best quality price ratio on the market.

We also offer bars and flat bars which are easier to handle for small foundries (see the bar and flat bar sheet). These products are mainly used for surface treatments, “float glass” (technique used for manufacturing flat glass), silverware and white metal casting. The METACONCEPT Group also collects used baths, off-cuts, scraps and white metal oxides.

Contact our recycling department to find out more.

|

Item no.

|

Designation

|

Density g/cm3

|

Solidus/Liquidus

|

Approximate weight

|

Packaging

|

|---|---|---|---|---|---|

| FE100055 | Tin ingot Minimum 99.90% quality |

7,3

|

232°C

|

Around 10 kg

|

Unit

|

| FE055548 | Lingot d’étain Minimum 99,85% quality |

7,3

|

232°C

|

Around 20 kg

|

Unit

|

| FE033081 | Pure lead ingot – Pb100 |

11,35

|

327°C

|

Around 25 kg

|

Unit

|

| MP0000SB | Antimony ingot – Sb100 |

6,61

|

631°C

|

Around 10 kg

|

Unit

|

| MP0000BI |  Bismuth ingot – Bi100 |

9,74

|

271°C

|

Around 10 kg

|

Unit

|

| MP0000IN | Indium ingot – In 100 |

729

|

156°C

|

Around 1 kg

|

Unit

|

| FE100135 | Ingot Sn97 – Sb2.5 – Cu0.5 |

7,27

|

232°C- 238°C

|

Around 20 kg

|

Unit

|

| FE029041 | Ingot Sn94 – Sb4 – Cu2 |

7,45

|

227°C- 265°C

|

Around 15 kg

|

Unit

|

| FE055376 | Ingot Sn30 – Pb70 Code J |

10,13

|

183°C- 250°C

|

Around 3,5 kg

|

Unit

|

|

Application

|

Properties

|

Uses

|

Characteristics

|

|---|---|---|---|

|

Tin ingot |

Malleable and moderately ductile

|

Creation of bronzes, manufacture of tableware, manufacture of organ pipes, tin plating, electroplating. If forms part of all solders.

|

Rust-proof

|

|

Lead ingot

|

High density Improves the “wettability”

|

Ships’ ballasts In industry, it is a component of welds and soft solders. Other application: roof sheet metal in the form of lead rolls. It is also used in the medical sector (for aprons to protect against x- rays)

|

Oxidises over time, unbreakable

|

|

Antimony ingot

|

Increases the melting temperature of the alloys, strengthens Increases in volume during solidification

|

Forms part of alloys for the creation of costume jewellery and tinware.

|

Moderately breakable metal

|

|

Bismuth ingot |

Lowers the melting point of the alloy. Increases in volume during solidification

|

Used in the composition of soft solders and low melting temperature alloys (alloys for fire safety systems in public places, radiotherapy, avionics, tube bending).

|

Very breakable metal

|

|

Indium ingot

|

Soft metal, lowers the melting point of the alloy.

|

Used in the composition of soft solders and low melting temperature alloys (alloys for fire safety systems in public places, radiotherapy, avionics).

|

Non-corrosive

|

The product safety information sheet below is available upon request from the METACONCEPT Group.

Fusion in crucibles or tanks.

The implementation procedure is specific to the alloy and its application. Contact the METACONCEPT Group’s technical department who, after you’ve selected the alloy and its form, will provide the appropriate implementation sheet.

To prevent burns caused by the molten metal, it is advisable to wear a protective apron, shoes, gloves, helmet and glasses.

Do not smoke at the workstation.

The workstation must be well ventilated.

Wash your hands when leaving the workstation.

Comments :

Always use a flux suited to the intended use. Contact our technical department to ascertain which product is most suited to your application.

All of the information contained in this document is provided for informational purposes only and the METACONCEPT Group will not be held liable for it.

Industrial Applications Of Tin

Tin is a non-ferrous metal that has been known and widely used since antiquity. It is silver-grey in colour, malleable and ductile. Tin is also known for its resistance to corrosion. As a result of these characteristics, tin can easily be used to create alloys.

Industry is now the largest consumer of pure tin ingots. It is used as a base material in various types of soldering and welding, such as lead-tin alloys and copper-tin alloys.

Tin is also used to create tinplate. Tinplate is a mild or extra mild steel sheet (carbon content less than 0.08%), less than 0.5 mm thick and coated with tin on both sides. It is used for the manufacture of metal food packaging (food preserves) and for the manufacture of packaging for various industrial products.

Various industrial machine parts are also made from tin, such as pumps, sintered parts or bearings. The anti-friction alloy is used, for example, as a bearing lining for turbines, diesel engines, railway rolling stock, presses, pumps and various industrial machines. These antifriction alloys contain 60-90% tin, antimony (5-15%), copper (5-10%) and lead (up to 15%). This alloy reduces the friction between the sliding bearing and the heavy load shaft.

Compared to the lead-based antifriction alloy, the tin-based antifriction alloy offers better thermal conductivity. It also provides a very low coefficient of expansion and friction. For these reasons, it is used in large machine bearings: high-speed steam engines, steam turbines and machine tools.

Finally, pure tin ingot is widely used in the electronics industry and for new technologies. Thanks to its low melting point (232°C) and its excellent electrical conductivity, it is used to bond electronic parts. Many tin-based alloys exist. Tin-indium, for example, has a lower melting point, below 70°C. Since 2016, the use of lead for soldering electronic components has been prohibited, as this material is toxic. Therefore, the tin-lead alloy with a melting point of 183°C has been replaced by a tin-silver-copper alloy with a melting point of 220°C.

In addition to the automotive, electronics, aerospace, shipbuilding, railway, steel and energy industries, tin is also used in the chemical sector. The metal and its derivatives are used, for example, to make glass anti-static or to enable infrared radiation to be reflected on windows.

At the current rate of consumption, the depletion of tin-based natural resources is estimated at 50 years. Therefore, to avoid waste, many industries are now turning to recycled and