Tin-based Laminates

The METACONCEPT Group’s laminates are tin-based alloys supplied in the form of sheets, plates, discs or foils with or without incorporated fluxes. We are able to offer external fluxes suited to the properties of the parts being assembled.

The main alloys used as laminates are tin-lead, tin-copper-antimony alloys and pure tin. We are also able to supply lead-silver alloys. All of these products are commonly used in areas such as the manufacture and repair of heat exchangers, silverware, packaging and labelling, the creation and mounting of countertops (bars), the creation of metallic braids, the assembly of electrical components, electronics, the military and pyrotechnics.

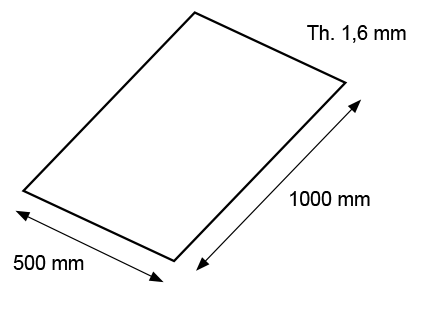

Sheets

The standard alloy used in the manufacture of tin sheets is Sn97 – Sb2.5 – Cu0.5. The sheets referenced below are always kept in stock. They are packaged in wooden boxes to protect them from scratches. They comply with the standard EN 611-1: 1995. They are also offered in pure tin.

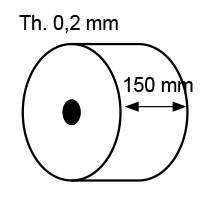

Rolls or foils

The METACONCEPT Group offers different types of laminates supplied on spools in foil form. Alloys with a high lead content can be laminated up to 0.125 mm. Alloys with a high tin content can be used to produce foils that are 0.030 mm thick. The maximum weight of a roll is generally between 25 to 35 kg depending on the alloy in question. The maximum standard width is 140 mm.Discs

Our disc cutting options depend on the thickness of the sheet as shown below:

- Diameters available: from 50 mm to 900 mm

- Thicknesses available: from 0.5 mm to 3 mm

Have you defined the type of application ?

Contact us Our technical staff will be happy to assist you in choosing the most suitable alloy and its form. The METACONCEPT Group also collects used baths, off-cuts, scraps and white metal oxides.

Contact our recycling department to find out more.

Dimensions and weights are given for informational purposes only and may vary depending on the production run.

This table shows the most commonly used alloys. For other types of alloys, please contact our technical department.

|

Item no.

|

Composition

|

form

|

Dimensions

|

Solidus /

Liquidus |

Density g/cm3

|

Approximate weight

|

Packaging

|

|---|---|---|---|---|---|---|---|

|

LA100005

|

Sn100

|

Sheet

|

1000 x 500 x 1 mm

|

232°C

|

7,29

|

3,64 kg

|

Wooden box unit

|

|

LA100065

|

Sn97 – Sb2,5 – Cu0,5

|

Sheet

|

1500 x 700 x 1,2 mm

|

227°C – 265°C

|

7,27

|

9,164 kg

|

Wooden box unit

|

|

LA100063

|

Sn97 – Sb2,5 – Cu0,5

|

Sheet

|

1500 x 700 x 1,4 mm

|

227°C – 265°C

|

7,27

|

10,7 kg

|

Wooden box unit

|

|

LA100064

|

Sn97 – Sb2,5 – Cu0,5

|

Sheet

|

1500 x 700 x 1,6 mm

|

227°C – 265°C

|

7,27

|

12,2 kg

|

Wooden box unit

|

|

LA100321

|

Sn98 – Sb1 – Cu1

|

Sheet

|

1500 x 700 x 1,8 mm

|

227°C – 265°C

|

7,27

|

13,7 kg

|

Wooden box unit

|

|

LA100044

|

Sn95 – Sb4 – Cu1

|

Plate

|

25 cm x 20 cm x 3 mm

|

227°C – 265°C

|

7,25

|

1,1 kg

|

Unit

|

|

LA100055

|

Sn95 – Sb4 – Cu1

|

Plate

|

30 cm x 30 cm x 2 mm

|

227°C – 265°C

|

7,25

|

1,309 kg

|

Unit

|

|

Appellation

|

Propertires

|

Uses

|

Characteristics

|

|---|---|---|---|

|

Sheet Sn100

|

Pure tin

|

Metal braids and various industries including food (e.g. refining Roquefort), packaging and labelling (e.g. labels for wine bottles)

|

Food-safe tin

|

|

Sheet Sn97 – Sb2,5 – Cu0,5

|

Lead-free alloy*

|

Silverware, tinware, creation and mounting of countertops

|

Food-safe tin, good hardness

|

|

Plate Sn97 – Sb2,5 – Cu0,5

|

Lead-free alloy*

|

Preparation of models for the creation of silverware and costume jewellery

|

Food-safe tin, good hardness

|

|

Plate Sn60 – Pb40

|

Alloy with 40% lead

|

Electrical industry, thermal fuses, seals, military equipment, pyrotechnics

|

Good conductivity

|

|

Sheet Pb97,5 – Ag2,5

|

Lead-silver alloys

|

Laminates for heat exchangers and the electromechanical industry

|

Good mechanical characteristics, good watertightness

|

(*) Lead-free alloys – European standard no. 2000 / 53 / CE

The product safety information sheet below is available upon request from the METACONCEPT Group.

The implementation procedure is specific to the alloy, its form and its application. Contact us the METACONCEPT Group’s technical department who, after selection of the alloy and its form, will provide the appropriate implementation sheet.

Precautions of use

To prevent burns caused by the molten metal, it is advisable to wear a protective apron, shoes, gloves, helmet and glasses.

– Do not smoke at the workstation.

– The workstation must be well ventilated.

– Wash your hands when leaving the workstation.

Comments :

Always use a flux suited to the intended use. Contact our technical department to ascertain which product is most suited to your application.

All of the information contained in this document is provided for informational purposes only and the METACONCEPT Group will not be held liable for it.